Comparison Injection Blow Molding to Extrusion

Blow Molding

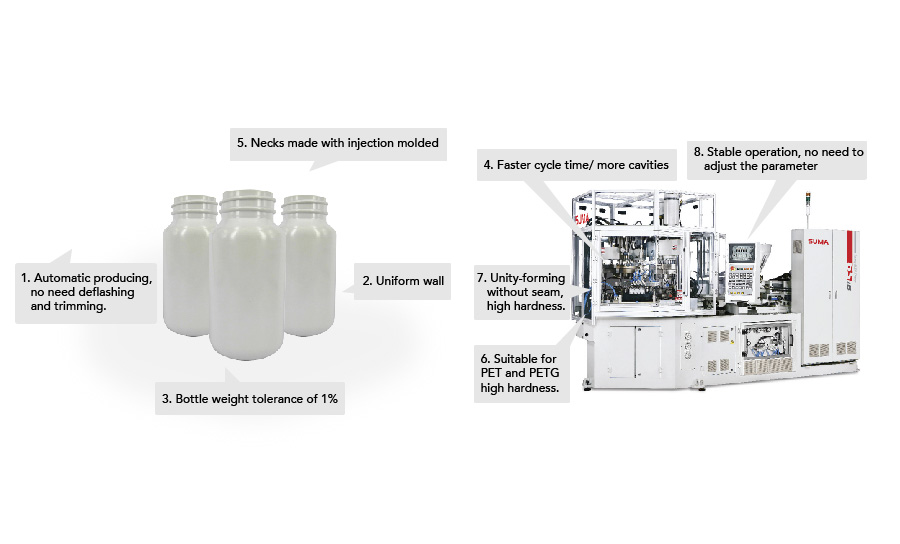

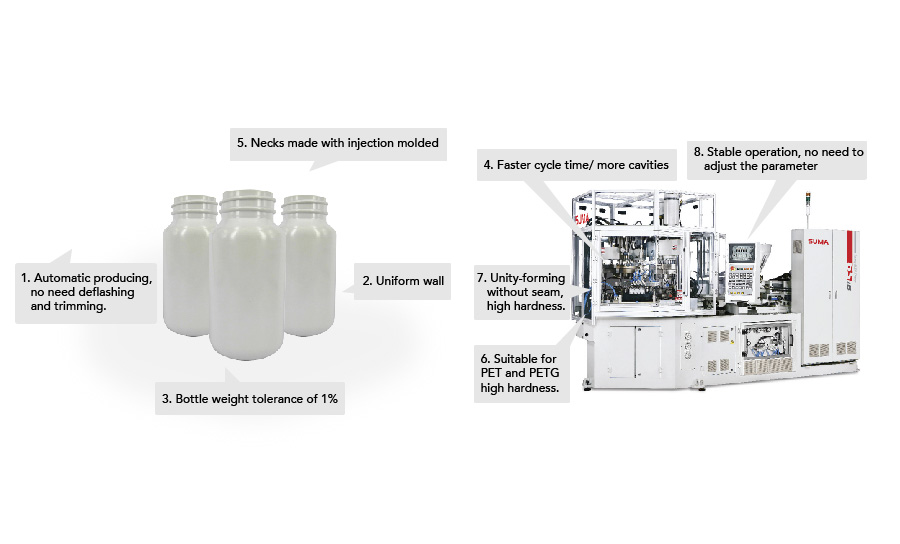

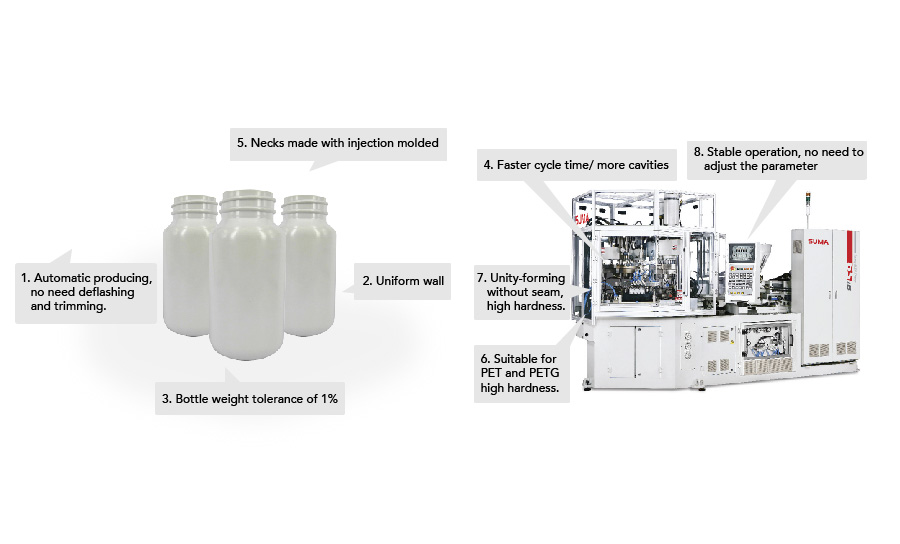

Injection Blow Molding

Automatic producing, no need deflashing and trimming.

Uniform wall thickness

Bottle weight tolerance of 1%

Faster cycle time / more cavities

Precise, stable and unity forming neck. Suitable for making

containers in clean room and factory.

Suitable for PET and PETG

Unity-forming without seam, high hardness.

Stable operation, no need to adjust parameter

Extrusion Blow Molding

Scraps during production, cost of wasting materials.

Wall thickness variation

Bottle weight tolerance of 3%

Slower cycle time / less cavities

Pollution caused. No stable neck size, cutting neck process is

necessary. Suitable for factory.

Only for PETG

Not unity-forming, visible Parting Line, Lower hardness

Need to adjust parameter during production.