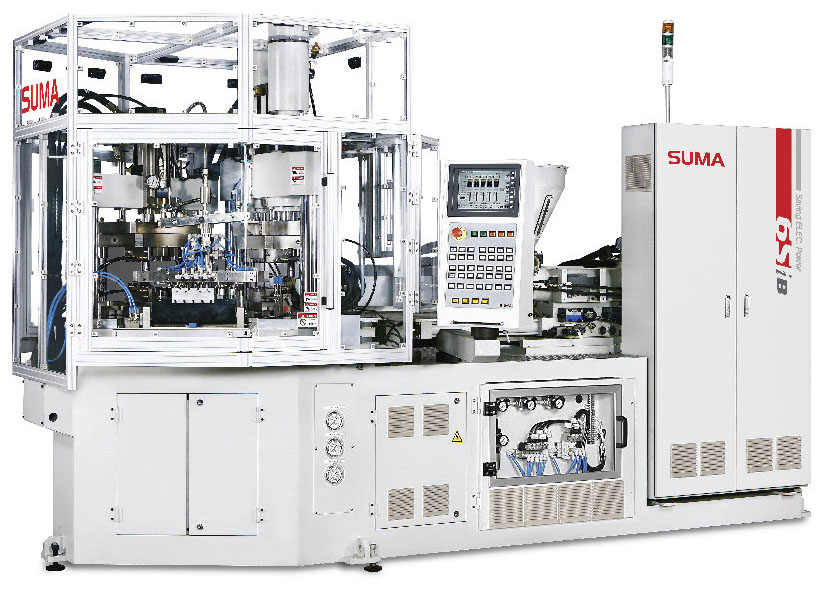

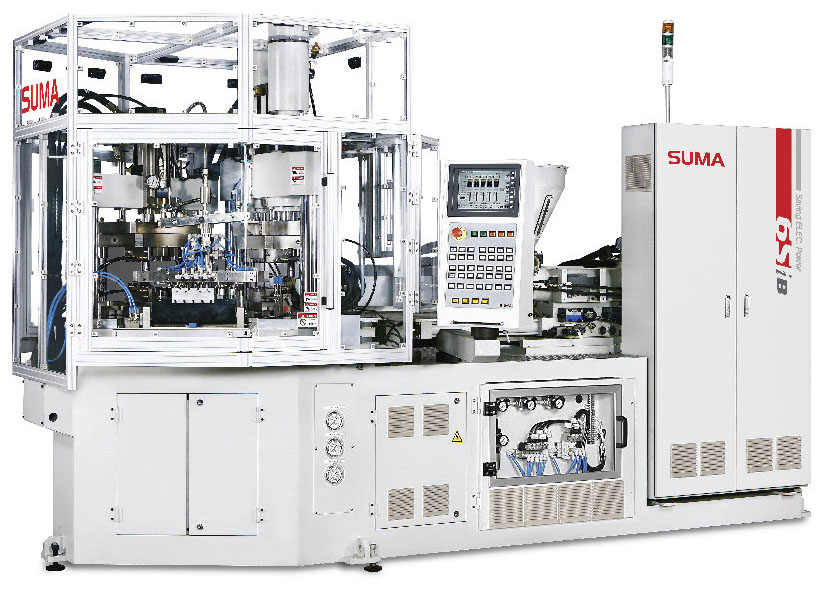

Introduction

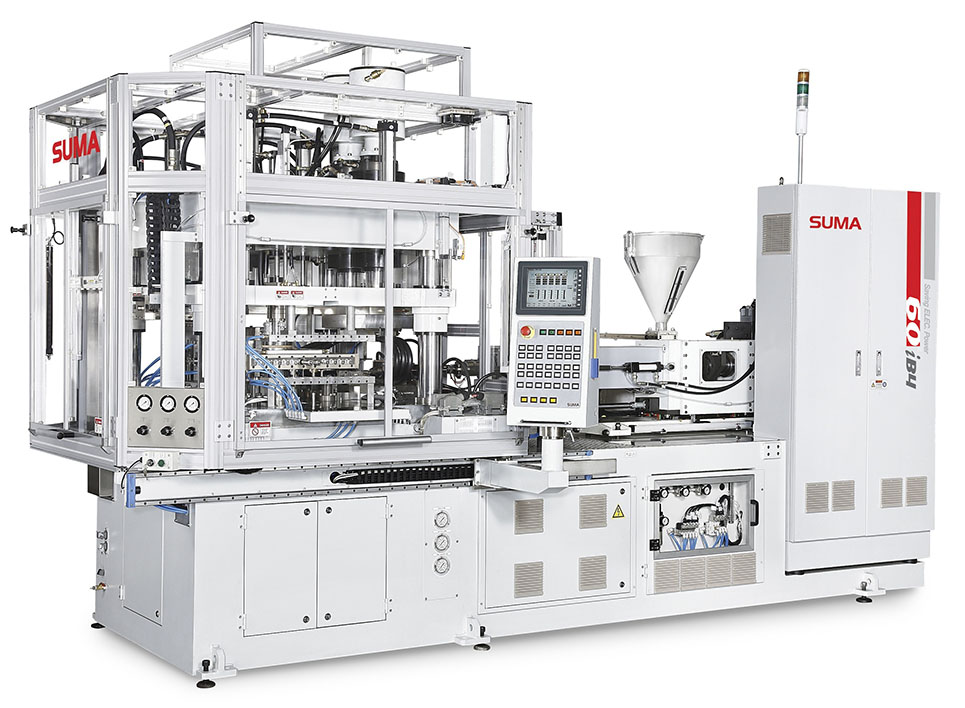

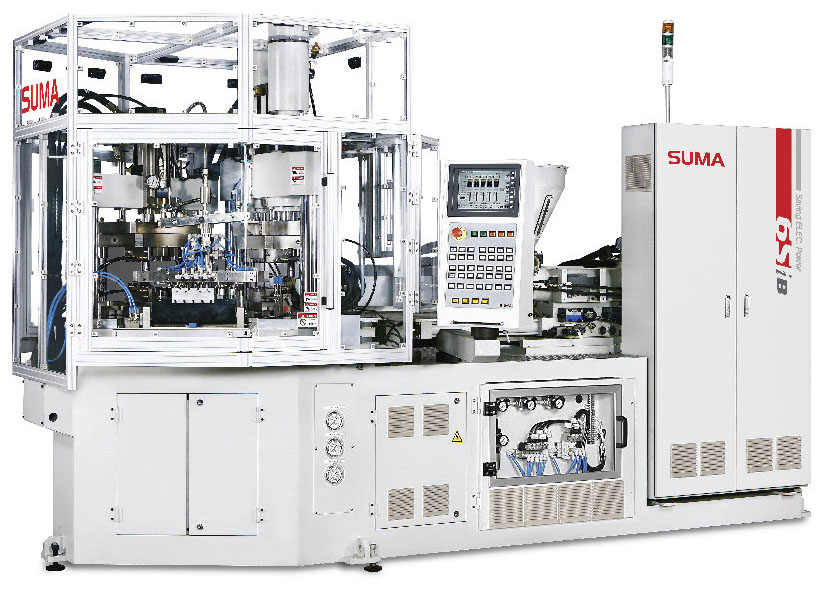

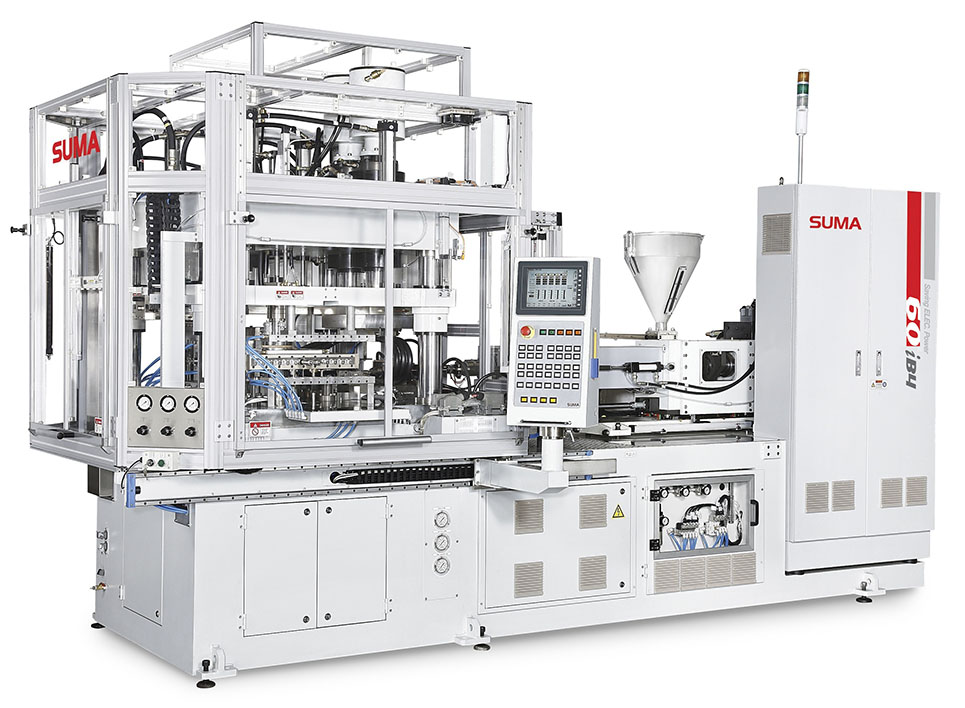

SUMA machines can go from preform to forming the bottles in

one step which is saving time and space.

Equip with core rods temperature control system makes

finished bottle better. (optional)

Precise and stable screw of neck.

Molding with multi-cavities per cycle. Suitable for large

production.

Automatic producing and no need to deflashing and trimming.

Unity-forming without seam.

Injection mold, blow mold, injection and plasticizing can be

separately controlled, so shorter cycle time by rapidly

processing.

Machine is stable, low vibration and low noise.

Independent electric control cabinet with dust-proof and

waterproof design.

Oil tank with filter and there is automatic oil constant

temperature control system.

Available material: PE, PP, PS, PC, PET, PETG/PCTA, etc.

Using on application of cosmetics, pharmacy, households,

beverage and so on.

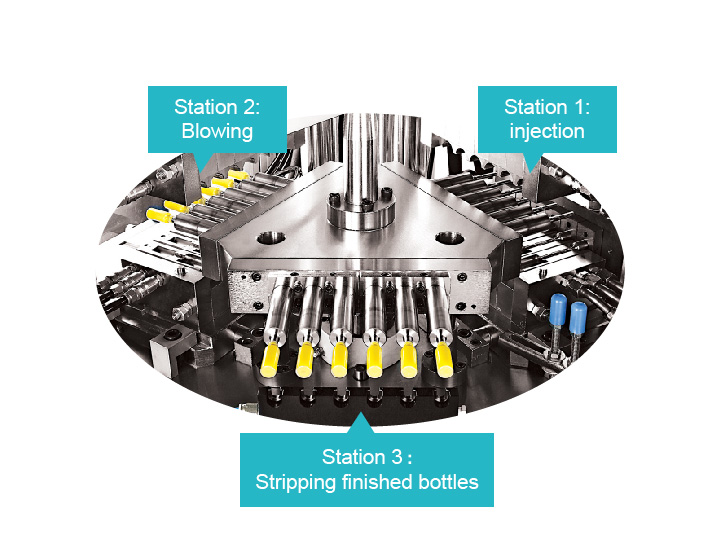

Producing process&Specifications

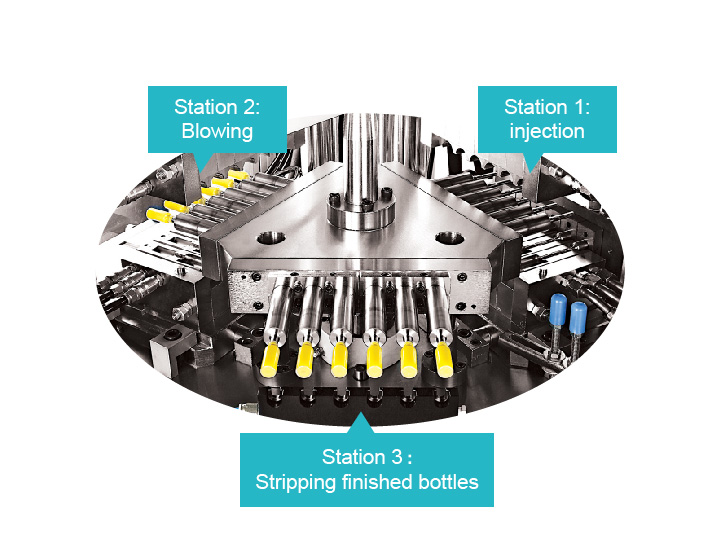

▪ 3 stations IBM producing process:

Station 1: Injection

Station 2: Blowing

Station 3: Stripping finished bottles

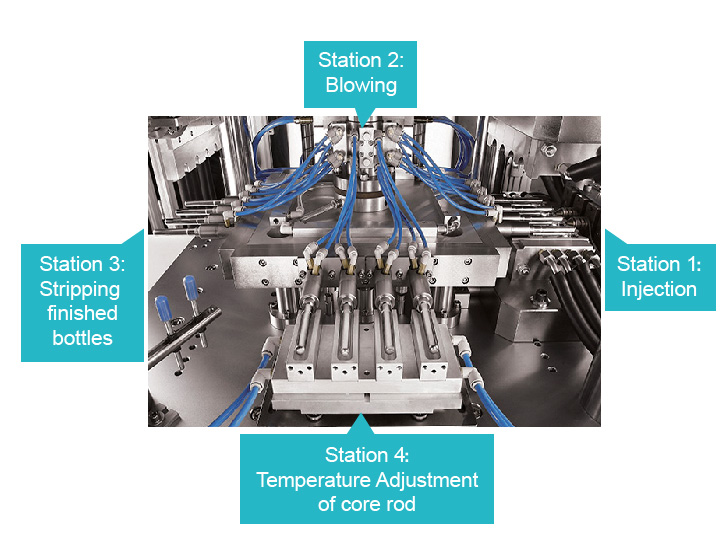

▪ 4 stations IBM producing process:

Station 1: Injection

Station 2: Blowing

Station 3: Stripping finished bottles

Station 4: Temperature Adjustment of core rod

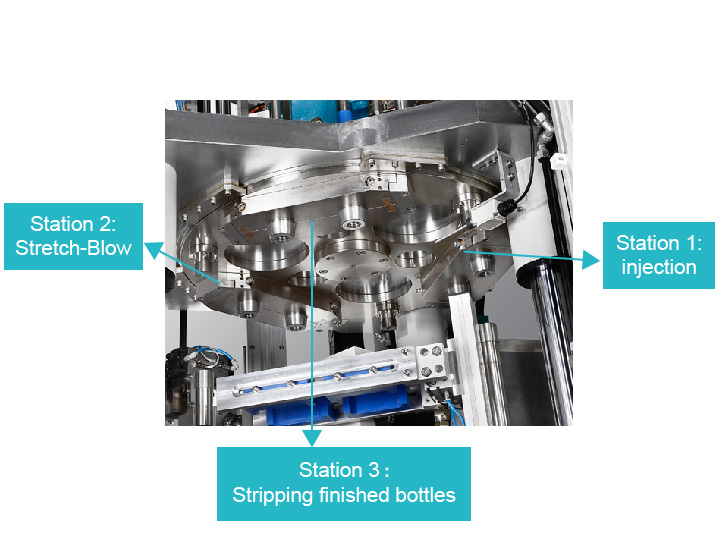

▪ 3 stations ISB producing process:

Station 1: Injection

Station 2: Stretch-Blow

Station 3: Stripping finished bottles

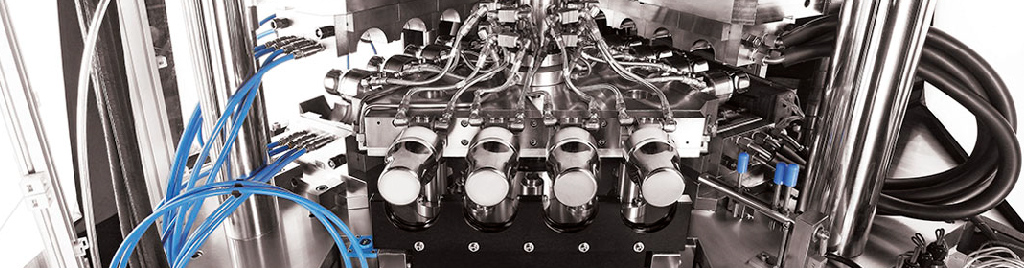

Mold

We provide professional mold design, manufacture and testing, the quality and precision are guaranteed.

The material of mold is made of stainless steel to prevent the pollution of rustiness and corrosion.

The properties of mold are high hardness, high strengh, high wear resistance and tough to extend the durability of mold.

Each cavity of mold is individual means easier to modify or dismantle for production and mold adjustment.

Suitable for producing the bottle neck diameter from 6mm to 70mm.

Position device of mold and mold base makes assembly faster and locate precisely.

Mold change can be finished within 3 hours.

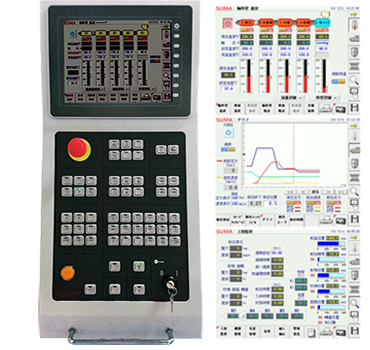

FUJI HMI CONTROL SYSTEM

10” Touch Panel

The humanized operation control panel which combines the touch screen and operation bottoms can directly entering the control values.

The touch screen with graphical interface is easy-to-learn for user.

Up to 10 steps of controlling and monitoring of injection, plasticizing,

decompression, hold pressure.

Decompression before and/or after plasticizing.

Real curve chart of producing. So, the engineer can fully control the producing

situation.

Integrated value monitor page.

All parameters in real values

Digital set points for all strokes, speeds, pressures and temperatures.

Automatic failure detect and showing the abnormal message on touch screen.

Powerful memory function can save hundreds of memory of control values.

Slow mode for mold exchange, more safety and convenience.